Electrical transformers, with their magnificent function, enable power transfer to the electrical loads for the ultimate end-use. Step-down transformers play a very important role in the operation of the routine domestic and industrial power applications. Spectacular models, sizes, and applications of step-down transformers are evident in this technologically advanced era satisfying the needs of domestic and industrial sectors. This post gives you brief information on these step-down transformers are for our daily routine power-based applications as well as complex industrial operations.

Step-Down Transformers – Definition

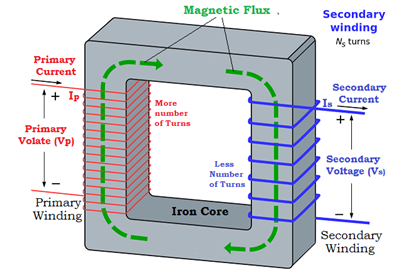

Voltage regulation and safety are the main functions of electrical transformers. By the name itself, it can be understood that step-down transformers decrease the voltage levels for the final use. In step-down transformers, the primary end has more turns than the secondary end. So, the final load receives a decreased voltage level for its successful function.

Step-Down Transformers – The Electrical Necessity for Domestic Uses

Step-down transformers are the most and should electrical requirements for various kinds of power applications in the domestic sector. Here are some of the major and important applications of step-down transformers.

- At distribution substations, they are used to decrease the voltage coming from the transmission lines. The transformers we see near our houses are step-down distribution transformers that decrease the voltage levels and supply for the end-user.

- Also, several smaller capacities of step-down transformers are applicable in the voltage wall adapters before the installation of the switching power supplies.

- Even in industries, the required decreased levels of voltage are met by customized step-down transformers. Characteristic machinery and equipment successfully run with the ultimate units of step-down transformers.

- They are used for getting larger currents for electric welding. Metal processing industries having induction furnaces also want efficient step-down transformers for melting metals. They also have suitable applications in commercial complexes, solar and wind applications, power plant applications, food processing units, cold storages, etc.

- Based on the applications, different types of step-down transformers are designed and manufactured. Large-sized ones are used for larger types of devices and smaller units are made for electronic equipment like radios, high fidelity equipment, etc.

- They are better safety means and protect against different unwanted hazards like blowing equipment, short-circuits, or fires.

Specialized Standards of Step-Down Transformers

Step-Down Transformers have an outstanding role in domestic power usage should be reliable, standard, in order to avoid power supply Interception. So, they have to be carefully constructed, designed, and also maintained well. Electrical transformer manufacturers supply standard units based on various standards across the globe. BIS standards (Indian Standard) assure standards of marking, quality control, quality certification, standardization.

Step-down transformers for domestic uses are generally manufactured as per IS 1180: 2014 (Part I), IS 2026 (Part I to XI). As a part of energy conservation and to reduce the power losses in the distribution sector, BEE & BIS introduced star rating & Energy levels for distribution transformers.

Energy Efficiency and Power Losses

Among several elements, energy efficiency and power losses are the significant ones to be considered to decide the transformer quality. Energy efficiency is the ratio of the output power to the input power.

Efficiency = Output / Input =( Input – Total Losses) / Input

Where the total losses include the no-load loss and load loss.

BEE (Bureau of Energy Efficiency) has given a star rating (One Star to Five Star) is given to the transformers based on the energy efficiency and power loss – (total losses at 50% and 100% loading of the transformer.) The ones with the highest loss segment are defined as star one and those with the lowest loss segment are defined as star five.

Here are certain key mandatory standard considerations as per the Bureau of Energy Efficiency, concerning for power losses, and star ratings of the transformers.

BIS (Bureau of Indian Standards) energy efficiency level has given a Level (Level one to Level three) to the transformers based on the energy efficiency and power loss – (total losses at 50% and 100% loading of the transformer.) The ones with the highest loss segment are defined as Level one and those with the lowest loss segment are defined as Level three.

As per the Bureau of Indian Standards, different levels of transformer ratings are available.

Maximum Total Losses and Impedance Values up to 11 KV Class Transformers

Servomax Limited – A Successful Transformer Manufacturer in India

Among the manifold options, Servomax Limited is the right one to get a reliable step-down transformer for your power needs. It is a trusted successful electrical transformer manufacturer in India with Brand SERVOCARE. It manufactures and supplies customized models of step-down transformers following the national standards. Also, with its great service orientation through Servocare, it enables repairing services of different kinds of transformers quickly.

Now, grab the chance to reach Servomax Limited and obtain reliable domestic and industrial power services.